Mill And Scrubber Components

Mill And Scrubber Components

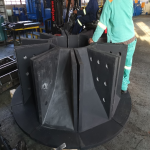

Grinding Mills play a key role in Comminution and Mineral dressing and are subjected to severe impact and abrasion from the Mineral being ground and from the Media that is introduced in the Mill to help break down the product.

With a complete range of mill liner components, from lifter bars and shell plates to centre cones and trunnion liners. Our mill and scrubber linings are specially designed to increase efficiency, reduce down time and lower the overall costs of your milling plant.

We are also capable of doing mill inspection and advising on liner selection and design.

Liner and Compound development is undertaken to target enhanced availability (reducing down time losses) with increased efficiency in grinding, and reduction in power draw.

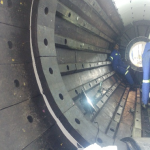

Shell Lining

Lifter Bar

Shell Plates

Manhole Doors and surrounds

- Available in a range of design and thickness.

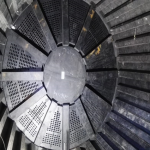

Head Linings

Head Plate

Grate Plate

Center Cone

Pulp Lifter or Dischargers

- Made to your requirement.

- Pulp Lifter ensure the correct flow per volume and can reduce bottlenecks which can have a negative impact on efficiency.

- Fabricated with a steel base and then rubber lined. These liners can be retrofitted with ceramic liner or rubber liner bolted in high wear areas to increase life span.

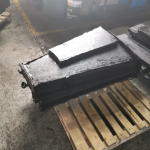

Trunnion Linings

- Made to your specific need trunnion Liners are easy to install and is meant to protect the trunnion from wear.

Contact Our Team

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

- Phone: +27 11 918 4410

- Neels: +27 82 857 4913

- Neil : +27 81 457 3329

- Email: neil@abbeywear.co.za

- Whatsapp: +27 81 457 3329

- Add: 13 Turf Road, Muswelldale, Boksburg, South-Africa.